How to Repair 3do Fz-10 Unable to Read Disc

This is a tutorial which explains how to lubricate the ii rails that the laser slides back and forth on. You may need to do this if your 3DO FZ-x tin can't read discs and has a laser that won't move. Details on how to diagnose this problem will be available shortly. Yous will demand

- 2 Phillips-head screwdrivers - a big ane to open the case and a small 1 to work on the disc bulldoze

- A small pair of pliers to remove the encompass over the CD drive

- A grease that is suitable for metal-on-metallic contact. I used white lithium grease, simply I've as well heard that pure silicone grease works. Y'all don't need very much.

Step i - Remove the disc drive [ ]

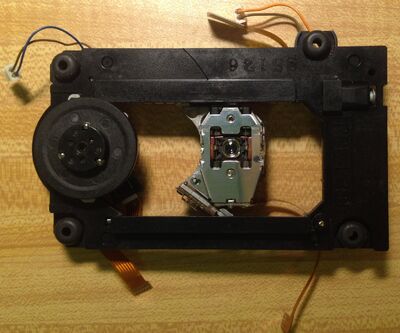

The CD bulldoze of a 3DO FZ-10

To piece of work on the CD bulldoze, you will need to remove it from the console. Follow this guide through step 6 to open the FZ-x and remove the bulldoze. Put the balance of the console aside and focus your attention on the drive.

Five cables extend from the CD drive: 3 ribbon cables and 2 wire pairs. Two of the ribbon cable are continued to the laser, and the other is connected to the spindle motor. The orange and brown wire pair controls the motor which controls the laser's position, and the blue and brown wire pair controls a switch which lets the bulldoze know if the light amplification by stimulated emission of radiation has reached the spindle.

Stride 2 - Remove the laser sled motor [ ]

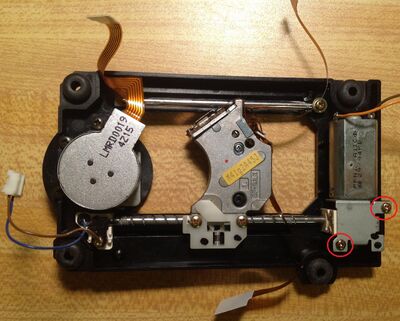

Remove the two screws circled in ruby.

Use your pocket-size Phillips-head screwdriver to remove the two screws show in the picture. The laser motor, which is connected to the orange and chocolate-brown wires, should now be lifted out easily. Be very gentle with the motor, because the connections between the wires and the motor are fragile; the kickoff time I worked on this drive I bankrupt off the brown wire, and while making this guide I broke off the orange wire. They're easy to resolder, just be conscientious non to brusk the wires with the metallic casing of the motor.

If you encounter any gunk on the plastic gear at the end of the motor, you should wipe it off.

Pace 3 - Remove the laser from the drive and lubricate the smoothen rod [ ]

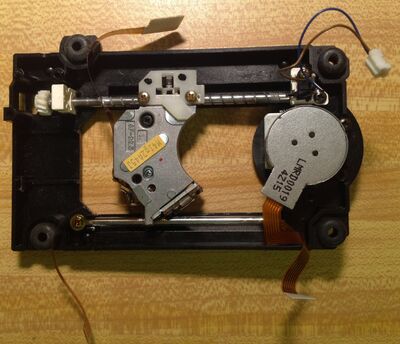

Disc drive with the laser sled motor removed

The laser rests on two runway: ane is completely smooth, and the other is connected to the laser motor and has a spiral blueprint. To remove it, lift upwards the fair plastic piece that the spiral rod passes through. Be careful though since the laser loosely rests on the smooth rod and is not connected to it, and so the laser may sideslip and hit your worksurface if you're not careful. Also, the end of the spiral rod near the spindle is just simply resting there, and so it volition fall as you remove the light amplification by stimulated emission of radiation.

Once you've done this, put the light amplification by stimulated emission of radiation and screw rod to the side. Go ahead and lubricate the shine rod now. If you lot desire, yous can remove the screw holding the rod in place to gain full access, but in my stance it is sufficient to lubricate the department of the rod that is accessible since that's what the laser comes in contact with. Either mode, you should get-go wipe off the old lubrication with a paper towel. Then apply the new grease, simply not likewise much.

Step four - Lubricate the spiral rod [ ]

3DO FZ-10 light amplification by stimulated emission of radiation removed from the drive

To remove the spiral rod from the laser, simply go along turning the plastic gear counter-clockwise until the rod is free. Comprehend it in grease and rub it into the spiral indentation. To remove the excess lube from the grooves, screw the rod all the way into the laser and all the way back out again, and repeat that a few times. Then wipe off any excess.

We've finished what nosotros came here to do. Spiral the rod back into the light amplification by stimulated emission of radiation, and don't forget the plastic tab that goes between the laser and the gear.

Step 5 - Put it all dorsum together [ ]

The just tricky part of putting the bulldoze back together is getting the laser and the spiral rail back into identify since you accept to exercise 3 things at about the same fourth dimension: you lot need to fix the light amplification by stimulated emission of radiation on the smooth rails, fit the plastic tab into its spot, and slide the end of the smooth rod in its hole. Here's what I recommend you exercise, and yous should employ the picture in step 3 equally a guide. Grip the laser from the top and bottom with your fingers, being careful of class not to touch the lens. If you do though, it's non the stop of the world and most likely you'll only go it dirty. Slide the plastic tab into place while holding the laser against the smooth rod. Note that the side that goes down (towards the top of the bulldoze) is the stop with the hole the spiral rod passes through. Once the plastic tab is firmly in place, slide the spiral rod into the hole. Yous should slide the rod with the laser and not push it through the light amplification by stimulated emission of radiation since the sudden jerky movement will probably make you drop everything. This will probably take a few tries, and even when you do get it, information technology won't be firmly connected until your reattach the laser sled motor.

Put the motor dorsum into identify and replace the screws. Before you put the bulldoze back in, audit information technology to make sure grease didn't get anywhere it shouldn't take, and wipe off any that did. Later on you've put the 3DO back together, you may have to try turning the system on a few times for the light amplification by stimulated emission of radiation to start moving over again. Attempt pushing the laser upwards and down the runway to spread the grease around more than. Once you get it to outset moving the first time, it should work consistently after that. Thank you, at present get play some 3DO!

Source: https://retroconsoles.fandom.com/wiki/3DO_FZ-10_Repair_-_Lubricate_the_Laser_Sled

0 Response to "How to Repair 3do Fz-10 Unable to Read Disc"

Post a Comment